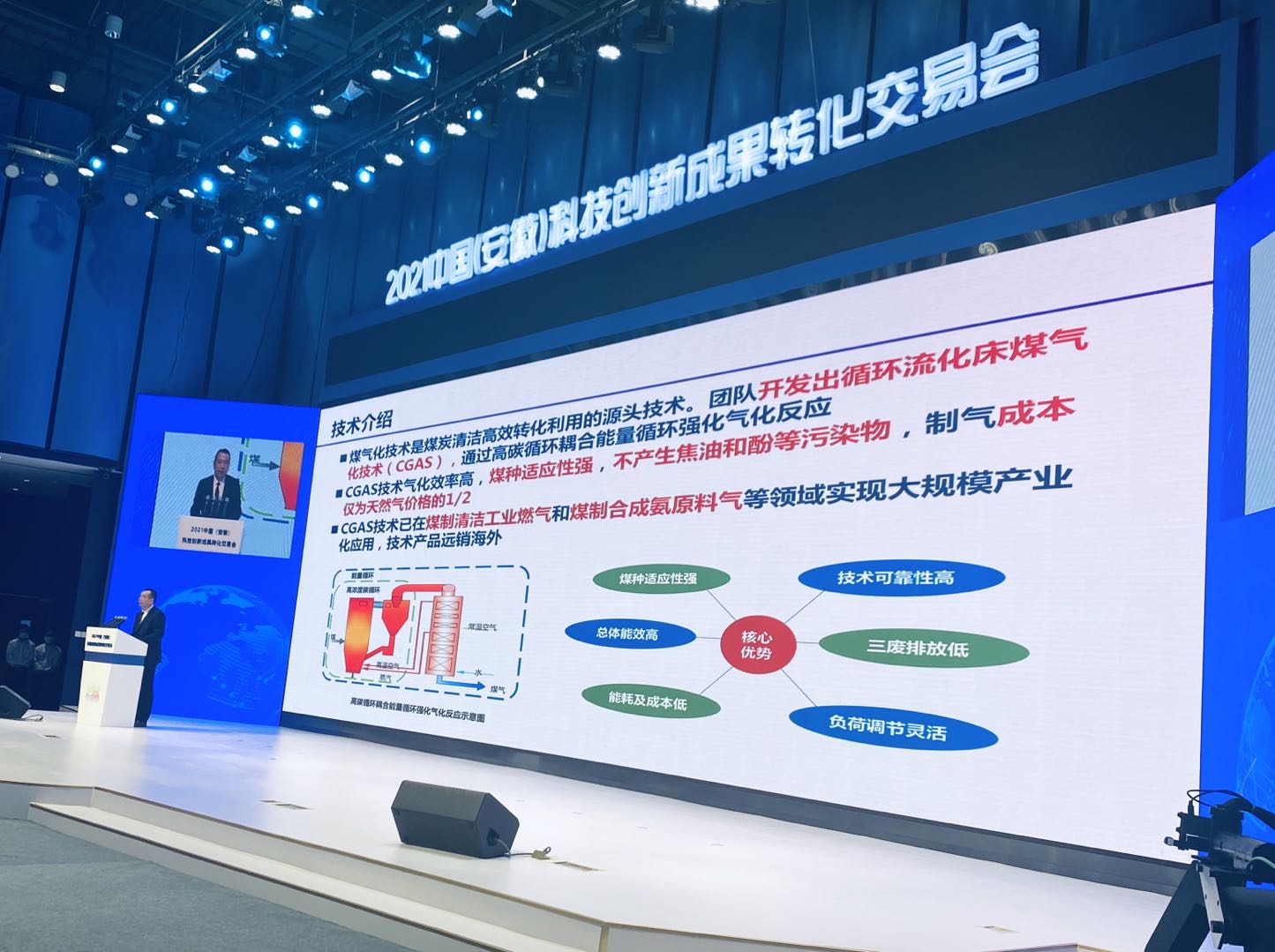

Recently, the “Development and Industrialization of Circulating Fluidized Bed Coal Gasification (CGAS) Technology” project by the Institute of Engineering Thermophysics, Chinese Academy of Sciences (CAS) was showcased as one of CAS’s five major achievements at the 2021 China (Anhui) Sci-Tech Innovation and Commercialization Fair. Its industrial arm, CAS Hefei Gasification Technology Co., Ltd. (hereinafter referred to as ZHGAS), drew significant attention. The rapid deployment of this project will advance carbon reduction in the coal chemical industry—a “major carbon emitter on the coal value chain”—supporting China’s Carbon Peaking and Carbon Neutrality goals.

CGAS Technology Debuts at China (Anhui) Science and Technology Innovation Achievements Transformation and Trading Fair

Accelerating Industrialization: Building a Platform Under Carbon Peaking and Neutrality

The coal chemical industry has long been a major carbon emitter globally. In China, where coal dominates the chemical feedstock due to resource endowment, approximately 80% of synthetic ammonia and methanol are coal-based—far higher than global averages—resulting in elevated carbon intensity.

In 2021, Carbon Peaking and Carbon Neutrality were formally included in China’s Government Work Report. At the Global Leaders’ Climate Summit on April 22, China reaffirmed its commitment to “peak carbon emissions by 2030 and achieve carbon neutrality by 2060”. This dual challenge has intensified focus on high-emission sectors like coal chemicals, oil, gas, and power.

Coal gasification is the cornerstone of clean and efficient coal conversion. Since the 1980s, the Institute of Engineering Thermophysics has pioneered research into clean coal utilization, systematically advancing CGAS technology for coal, waste, and alternative fuels. Over the past decade, the institute developed CGAS technology, which resolves traditional gasification challenges such as limited coal compatibility, high pollution, and costs. For example, in the synthetic ammonia industry—where gasification accounts for over 60% of total energy consumption—CGAS could reduce annual CO? emissions by 10 million tons if applied to China’s remaining 40% fixed-bed gasifiers (producing 20 million tons annually).

Notably, CGAS is one of the few industrialized next-generation gasification technologies in China. Its success stems from both technical superiority and strategic partnerships. In 2016, the institute partnered with Anhui Chaohu Economic Development Zone to establish ZHGAS, which holds core patents for CGAS. Supported by CAS’s Hongguang Initiative, ZHGAS has rapidly industrialized CGAS in clean industrial gas and synthetic ammonia feedstock gas, deploying it across alumina, magnesium metal, and foundry industries.

Implementation Milestones: Industrial-Scale Demonstration Systems

CGAS’s strengths—broad coal adaptability, low emissions, and cost efficiency—have driven its adoption in syngas and industrial gas production. Key projects include:

Xinjiang Yihua Coal Gasification Facility (High-Alkali Coal)

Replaced 20 fixed-bed gasifiers with 3×60,000 Nm3/h CGAS oxygen-enriched gasifiers.Solved challenges of high-alkali coal (strong fouling, slagging, variable ash melting points).Reduced ton-ammonia costs by over ¥200 while enabling clean utilization of Xinjiang’s vast high-alkali coal reserves.

Xinjiang Yihua Coal Gasification Facility Site

Guizhou Hongsheng Synthetic Ammonia Retrofit (Anthracite)

Deployed 1×60,000 Nm3/h CFB gasifier to replace 20 intermittent fixed-bed units.Overcame anthracite’s low reactivity and thermal instability.Eliminated tar, phenolic wastewater, and cyanide hazards while boosting automation.

Guizhou Hongsheng Chemical Feedstock Gas Source Revamp Project

Indonesia Xiangsheng CGAS Oxygen-Enriched Gasification Project

ZHGAS actively responded to China’s “Belt and Road” Initiative by undertaking the Xiamen Xiangsheng CGAS Circulating Fluidized Bed Oxygen-Enriched Gasification Project in Kendari City, Southeast Sulawesi, Indonesia. The project involves constructing a gas supply station for a local 2.5-million-ton stainless steel integrated smelter.

CGAS technology fully leverages the local lignite’s advantages, such as high reactivity and excellent grindability, significantly reducing energy consumption in deep coal processing. Currently, three gasifiers have been completed and put into operation, resolving noise and pollution issues from the previous pulverized coal injection process. The operational performance has earned acclaim from the project owner.

Leveraging CGAS technology, ZHGAS has established multiple demonstration projects, showcasing the technology’s application across diverse sectors and validating its strong adaptability to various coal types. Moving forward, ZHGAS will continue to explore cleaner and more efficient solutions for the coal chemical industry, enhance fossil energy utilization efficiency, and advance cleaner coal utilization. By delivering economic benefits to enterprises, ZHGAS also commits to its social responsibility of supporting the Dual Carbon goals (peak carbon emissions and carbon neutrality).

Future Focus: Full Industry Chain Integration and Key Technology Expansion

For gasification byproducts like fly ash, ZHGAS developed fly ash combustion and gasification technologies to achieve cascaded coal utilization and gas-power-heat cogeneration. Partnerships with Shandong Rongxin Group and Henan Linzhou Fengbao Pipe Industry are advancing fly ash resourceization.

Building on this, ZHGAS will expand R&D into coal-based solid waste treatment, targeting high-value applications to empower the environmental sector.

Moving forward, ZHGAS and the institute’s R&D team will pursue a “dual-drive” strategy—bridging fundamental research and industrialization through academia-industry collaboration. This approach aims to fast-track lab-to-market transformation, ensuring scientific achievements fuel modernization.